OVERVIEW

Mobile plant can not only be operated as a single device, but is also widely used in two-stage, three-stage, or four-stage crushing processes to meet various crushing needs from coarse crushing to medium crushing, fine crushing, and ultra-fine crushing. According to needs, corresponding mobile screening plant can also be equipped to achieve integrated crushing and screening functions. The mobile plant emphasizes the essence of complete functionality, stable performance, and strong practicality. The perfect matching between various systems greatly increases the equipment output. Compared with fixed crushing and screening plant with the same installed power, the equipment performance and stability are more reliable, the functions are more powerful and diverse, and the processing capacity of the entire plant is greatly improved, with a wider range of applications.

The mobile plant is with the most advanced modular design: vehicle universality and host interchangeability.

The mobile plant has a common body for multiple models, and each unit host can be quickly interchanged. With the need to invest in the cost of a single main equipment and electronic control system, in a short period of time, the mining area can achieve unit exchange on the same body, meeting on-site needs. The perfect matching between the various systems of the mobile plant enables the equipment to have more comprehensive crushing functions, adapt to a wider range of occasions, and maximize the value of customer equipment.

ADVANTAGES

Lightweight design

It adopts ship style steel structure and low vehicle chassis with light weight. The volume is controlled reasonably. Hidden style traction frame is easy to be packed up and put up. The transportation turning radius is very small.

Hydraulic regulation

Feeding guard is lifted by hydraulic pressure, easy to be loaded and unloaded, conveniently and reliably to be fixed.

Component upgrade

Feeding guard adopts hierarchical type with two layers structure which provides prerequisites for widening.

Intelligent control

The vehicle control cabinet is equipped with high-tech LCD touch screen and PLC control system. LCD touch screen with HMI dialogue function makes it possess the functions of key start, misuse tips and protection, electrical control operations, fault and safe tips. It is convenient, efficient and secure.

Easy to adjust

Height of belt conveyor is adjustable. It also can be twisted and folded.

Hydraulic supporting leg design easy to operate

Landing legs adopt hydraulic lift mode which is convenient for operation and reliable performance.

Reasonable design

Feeding guard adopts hierarchical type with two layers structure which provides prerequisites for widening.

High crushing efficiency with pre-screening function

Grizzly bars of the feeder is capable to separate out the small-sized material as the wastes. By adopting the automatic separatory hatch door, materials in the wastes hopper would flow either with the side-opening belt conveyor, or with the main materials.

Beautiful and practical

With overall streamlined body design and metallic paint spraying, this plant is the perfect combination of mechanics and aesthetics.

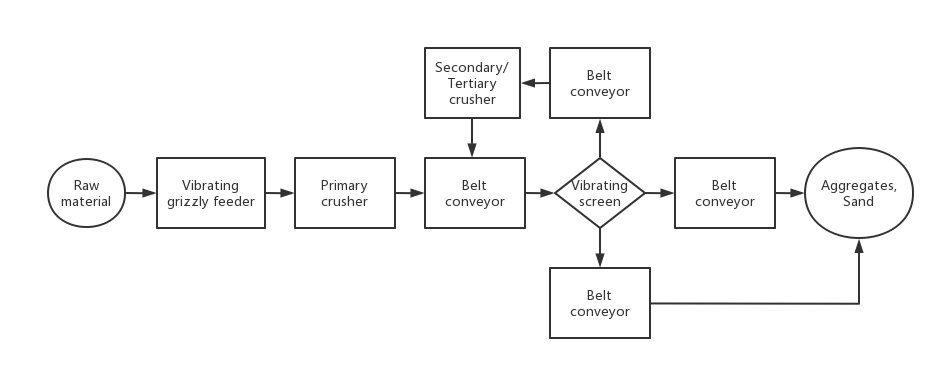

WORKING PRINCIPLE