OVERVIEW

A crane used in highway and bridge construction projects is known as a gantry crane. Based on its construction and characteristics, it can generally be categorized into four types: light-duty and small-sized lifting equipment, gantry cranes, portal cranes, and tower cranes. Gantry cranes are a classic type of crane used in construction. They can span a large horizontal area and have a significant lifting capacity. Common types of gantry cranes include single-girder and double-girder gantry cranes. Gantry cranes are suitable for use in large manufacturing industries, heavy industries, shipbuilding, automotive manufacturing, and other applications. They are often employed for the production, loading and unloading, transportation, and packaging of heavy items.

ADVANTAGES

Heavy Lifting Capacity: Gantry cranes are a type of heavy-duty lifting equipment known for their high lifting capacity. Typically, the lifting capacity of a gantry crane ranges from 5 tons or more and can even reach several hundred tons.

Wide Operating Range: Gantry cranes offer a broad operating range. They can be used not only for heavy lifting, moving, and stacking operations within a fixed lifting area but also for high-altitude operations, large component assembly, and other tasks in different work areas by traveling along tracks.

Rational Structure and Excellent Stability: The primary load-bearing component of a gantry crane is the bridge structure. Compared to other lifting equipment, gantry cranes have a more stable structure and greater load-bearing capacity, making them suitable for lifting operations in various industrial settings.

WORKING PRINCIPLE

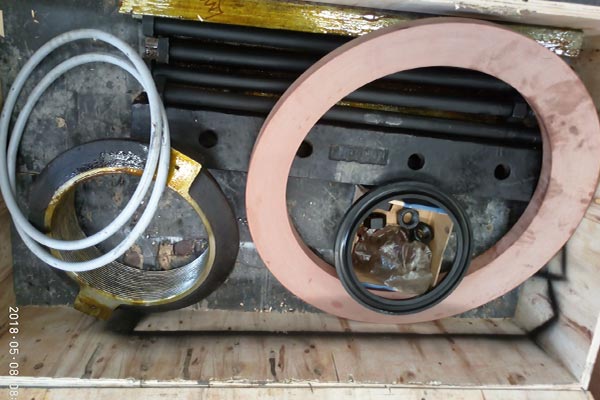

A bridge crane, also known as a gantry crane, consists of several key components, including the bridge structure, hoisting machinery, electric motor, and electrical control system. The bridge is the main load-bearing structure of the crane, spanning over the working area and typically constructed from welded steel.

The hoisting machinery includes components such as the lifting hook, hoisting arm, and the trolley used for lifting and horizontal movement of goods. An electric motor provides the power for the crane's operations by driving the mechanical components. The electrical control system is responsible for managing the crane's movements, stops, and various actions.

The working principle of a bridge crane can be divided into the mechanical motion principle and the electrical control principle:

1.Mechanical Motion Principle

1)Hoisting Mechanism: The hoisting mechanism involves lifting loads and consists of a hook and a winch or drum. An electric motor, typically connected to a reduction gearbox, drives the drum's rotation. This rotation winds or unwinds the wire rope, allowing the lifting hook to raise or lower the load.

2)Trolley Travel: The crane's trolley travels horizontally and is mounted on rails. An electric motor drives the wheels on the trolley, allowing it to move along the rails, facilitating horizontal load movement.

3)Bridge Travel: The entire crane, including the bridge and trolley, can traverse along a set of tracks on the overhead structure. An electric motor drives the wheels of the crane, enabling it to move along the bridge structure's tracks.

2.Electrical Control Principle

The electrical control system of a bridge crane manages the operation and various movements. It usually consists of a main control panel, an operator's control box, and sensors. The main control panel includes components like contactors, relays, and controllers, which control the electric motor's operation and various crane actions. The operator's control box allows crane operators to control and monitor the crane's movements. Sensors are used to monitor and provide feedback on the crane's status.

In practical applications, bridge cranes are valued for their ability to improve work efficiency, reduce manual labor, and enhance safety and stability in lifting and material handling operations.