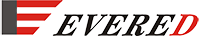

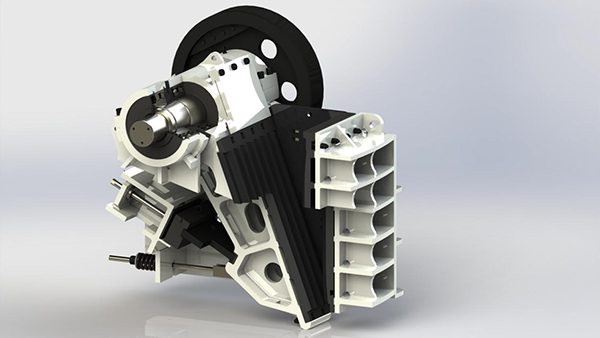

OVERVIEW

The Jaw crusher is regarded as the most common crusher internationally with high crushing ratio, well-distributed final product size, simple structure, and high efficiency, etc. It is suitable to be the primary and secondary crusher featuring of high crushing ratio and well distributed final products size. The crushing ratio can reach 4-6 with well-distributed final product size. It can be applied in many industries, such as metallurgical industry, mining, smelting, building material, highway, road and railway building, water conservancy and chemical industry.

ADVANTAGES

-

1, Central lubrication device is installed, so the bearing is easy to be lubricated

-

2, Wedge block is installed to adjust the discharging part, which is simpler, safer and faster than the old spacer on the crusher

-

3, Movable jaw assembly is made by high quality cast steel, which is durable

-

4, Heavy type protecting plate is installed for bearing seat, in order to avoid the damage of bearing seat

-

5, Crushing chamber adopts "V" structure which could make actual feed width comply with nominal one

-

6, Teeth-shape side plate makes the available area of jaw plate longer, and enhances the capacity

-

7, Pressing bar and supporting bar are used to fix the jaw plate, which makes installation faster

-

8, Bearing is used with larger model and higher load. Its higher load capacity and effective oil seal will lengthen the life of bearing.

-

9, Integral cast steel structure is adopted for bearing seat, which matches well with the crusher frame, and radial strength of the bearing seat is highly strengthened.

- 10, Supporting bar under jaw crusher protects movable haw and frame from being worn down.

WORKING PRINCIPLE

The motor drives the movable jaw up and down through eccentric shaft. The angle between toggle plate and movable jaw increases when movable jaw moves up. So the movable jaw will be closed to the fixed jaw. The stuff will be crushed in this process. The angle between toggle plate and movable jaw decreases when movable jaw moves down, movable jaw moves away from fixed jaw under the movement of draw rod and spring, the material will be discharged from the discharging opening. This process is repeated. The movable jaw will crush and discharge the stuff periodically to achieve mass production.