OVERVIEW

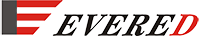

The multi-cylinder hydraulic cone crusher is a new type of high-efficiency crusher developed and designed by our company based on more than two decades of experience in the crushing industry, along with the advancements in modern industrial technology. It extensively incorporates advanced crusher technologies from the United States, Germany, and other sources. The multi-cylinder hydraulic cone crusher integrates mechanical, hydraulic, electrical, and automation technologies, representing the most advanced crusher technology in the world. It offers numerous advantages that traditional crushers cannot match, including high crushing efficiency, low production costs, easy maintenance and adjustment, and excellent product particle size. This crusher can be widely used in medium, fine, and ultra-fine crushing operations, making it the latest generation product that has replaced spring cone crushers and general hydraulic cone crushers in the mining and construction industries.

With the development and progress of society, the mining and aggregates industry not only demands high production capacity from crushing equipment but also places increased emphasis on energy efficiency, excellent product particle size, ease of maintenance and adjustment, and prompt and comprehensive service. The multi-cylinder hydraulic cone crusher is specifically designed to meet these requirements. It features a new crusher structure, optimized laminated crushing chamber, which results in high crushing efficiency and excellent product particle size. The new hydraulic control system facilitates convenient and precise maintenance and adjustment during the crushing process.

ADVANTAGES

- Unique inter-particle crushing method

-

Inter-particle crushing works between materials that increases the working life of mantle and bowl liner;

-

Provide a more consistent gradation and superior cubic products. Better performance in the construction and sand making area.

- Integration of the hydraulic station and lubrication system

-

Small footprint and easy maintenance;

-

Save 20% lubrication oil;

-

Germany AKG air cooling system avoids the disadvantage of water cooling system, such as lack of water and leakage of water;

-

Larger flow oil pump will guarantee the stability of oil flow;

-

Temperature sensors keep tracking of the return oil temperature, which will guarantee the stable performance.

- Advanced hydraulic system

-

Larger diameter tubing and larger capacity hydraulic accumulator improve the stability and response sensitivity;

-

Hydraulic motor setting adjustment and lock cylinder make it easy to reset the CSS; The hydraulic tramp release cylinders make it easy to pass tramp iron and clean the cavity;

-

Less downtime will cut the maintenance cost.

- Optimized liner retention technology

-

The thicker liners increase reliability and service life;

-

Advanced liner retention technology greatly simplifies the liner change. Epoxy resin is not needed, which will cut the manpower and time cost.

- Safe and reliable

-

Equipped with the Siemens PLC, touch screen, and intelligent control system, operation and data recording is more simple;

-

Larger bearing area, larger bearing capacity and longer service life;

-

The overall casting frame with box beam design characterized by larger strength;

-

The interior of the crusher is protected from dust by the adoption of multiple sealing protection, such as positive pressure dust prevention system, U-T seal and contact-type spherical floating seal.

- Final aggregates with cubic shape

WORKING PRINCIPLE

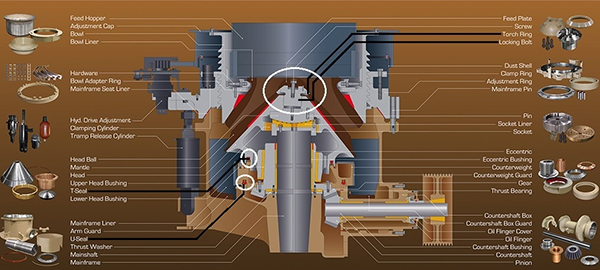

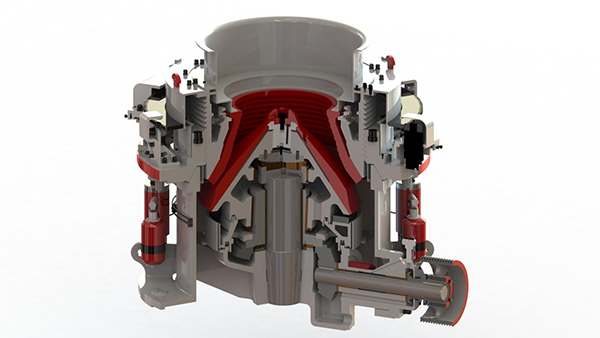

Multi-cylinder hydraulic cone crusher mainly consists of frame, transmission parts, eccentric sleeve, main shaft assembly, supporting sleeve assembly, movable cone assembly, fixed cone and the auxiliary equipment such as electric system, lubrication system, hydraulic system, etc. The crusher is with characters of special design, smooth operation and high-efficiency. It adopts the lamination crushing principle, which helps increase the cubical output and reduce the needle-like one. The crusher equipped with the hydraulic insurance system such as insurance hydro-cylinder, locking hydro-cylinder and pushing hydro-cylinder, etc. The insurance hydro-cylinder not only has the insurance-keeping function but also to jack up the fixed cone and supporting sleeve assembly for the clearance of the cavity. With this function, problems can be solved without disassembling the spare parts. The locking hydro-cylinder ensures the machine’s stability in operation. The pushing hydro-cylinder makes it easy to adjust discharging range.

The eccentric sleeve is rotate through motor with v-belt, transmission shaft, and umbrella-shaped gear. Meanwhile it drives the movable cone to do swing movement, making the movable cone be near and off the fixed cone. By doing this, the material is crushed and discharged though the discharging opening.