OVERVIEW

The TD75 belt conveyor is a general-purpose conveyor known for its advantages of high conveying capacity, low operating costs, simple structure, and easy maintenance. It is widely used due to its versatility in handling a wide variety of materials, including bulk materials, as well as various goods like boxes and packaging bags. This type of conveyor finds extensive applications in industries such as metallurgy, mining, coal, ports, hydropower, and chemical sectors. It comes in both fixed and mobile structures and uses different types of conveyor belts, including rubber, plastic, and steel core belts.

The working environment temperature for belt conveyors typically ranges from -10°C to +40°C, with a requirement that material temperatures do not exceed 70°C. Heat-resistant rubber belts can be used for conveying materials with temperatures below 120°C. When conveying materials containing solvents such as acids, alkalis, or oils, oil-resistant and acid-resistant rubber or plastic belts should be employed.

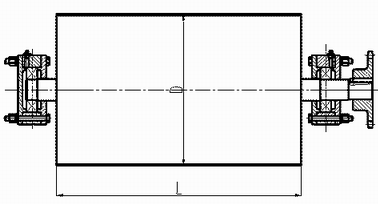

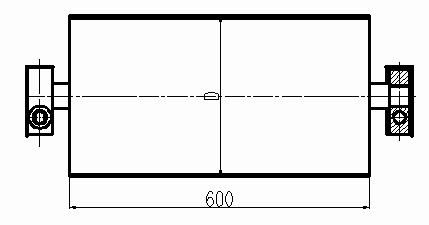

The belt width of belt conveyors can range from 500, 650, 800, 1000, 1200, to 1400mm. Users can determine the layout of the conveyor and select the appropriate belt width, number of fabric layers, and belt thickness based on factors such as the conveyor's length, material type, and conveying capacity through calculations.

ADVANTAGES

High conveying capacity

The main technical parameters and belt conveyors are trending towards larger sizes to meet the requirements of highly productive and efficient production, with annual outputs exceeding 3 to 5 million tons.

Easy maintenance

It has a straightforward design and simple structure that is easy to maintain

Low energy consumption and high efficiency

Due to the lightweight nature of its moving components and minimal unproductive load, belt conveyors have low energy consumption and high efficiency compared to other continuous and non-continuous transport methods.

Strong versatility

It offers robust conveying capabilities over long distances, is suitable for outdoor operations, and can be easily integrated into programmed control and automated operations.

Multi-drive systems and power balance

The use of multiple-drive systems, intermediate drives, and techniques for power balance and changing the direction of conveyor operation have removed theoretical restrictions on the length of single conveyor operation. This also ensures the versatility, interchangeability, and reliability of unit drives within the conveyor system.

Advanced and high-reliability key components

Various advanced high-power drive units with speed control, high-speed rollers with long lifespans, self-cleaning drum devices, efficient belt storage devices, and fast self-moving tail units are utilized to enhance reliability and performance.

WORKING PRINCIPLE

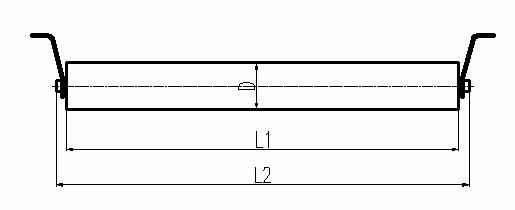

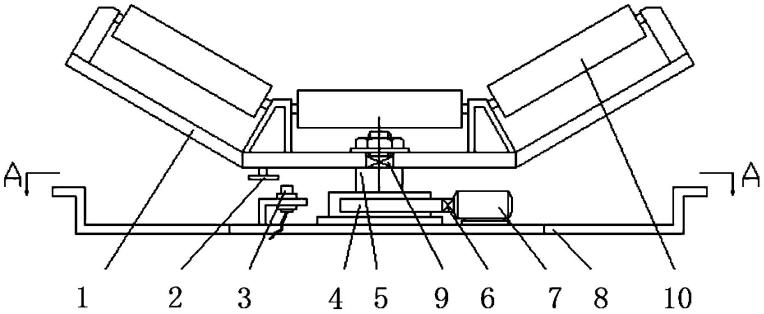

The TD75 belt conveyor is a mechanical system that operates based on the principles of friction to continuously transport materials. Its working principle is as follows: a continuous loop of conveyor belt is formed by wrapping it around the driving pulley and the tail pulley, creating a closed circular belt. The upper and lower strands of the conveyor belt are supported by upper and lower idler rollers, and a tensioning device ensures the necessary tension for the normal operation of the conveyor belt.

During operation, the driving pulley drives the conveyor belt to move through friction. Materials are loaded onto the conveyor belt and move along with it, thereby accomplishing the conveying task. Typically, materials are transported using the upper strand of the conveyor belt, and unloading occurs when the conveyor belt changes direction as it passes over the head pulley.